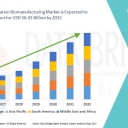

The global next-generation biomanufacturing market size was valued at USD 26.61 billion in 2024 and is expected to reach USD 56.43 billion by 2032, at a CAGR of 9.85% during the forecast period

IntroductionThe Next-Generation Biomanufacturing Market represents the global industry focused on advanced biological production systems used to manufacture biologics, vaccines, cell and gene therapies, enzymes, and bio-based products. This market integrates innovative technologies such as single-use systems, continuous bioprocessing, synthetic biology, and digital manufacturing platforms to improve efficiency, scalability, and sustainability.

The global importance of next-generation biomanufactauring continues to expand due to rising demand for biologics, personalized medicine, and sustainable production methods. Governments, pharmaceutical companies, and biotechnology firms rely on advanced biomanufacturing to ensure secure supply chains, rapid product development, and cost-effective production.

Learn how the Next-Generation Biomanufacturing Market is evolving—insights, trends, and opportunities await. Download report: https://www.databridgemarketresearch.com/reports/global-next-generation-biomanufacturing-market

The Evolution

The evolution of biomanufacturing began with traditional batch-based fermentation and cell culture systems used primarily for antibiotics and basic biologics. Early production models relied on large stainless-steel bioreactors, manual processes, and long development timelines.

Key milestones emerged with the commercialization of recombinant DNA technology, enabling large-scale production of insulin, growth hormones, and monoclonal antibodies. This period marked the foundation of modern biopharmaceutical manufacturing.

The transition toward next-generation biomanufacturing accelerated in the early 2000s with the adoption of single-use bioreactors, modular facilities, and process analytical technologies. These innovations reduced contamination risks, lowered capital costs, and increased operational flexibility.

Recent shifts in demand focus on speed, scalability, and precision. The rise of cell and gene therapies, mRNA vaccines, and personalized biologics has driven the need for continuous processing, automation, and advanced digital control systems. Biomanufacturing now emphasizes adaptability to small-batch, high-value products alongside large-scale production.

Market Trends

The next-generation biomanufacturing market is shaped by strong technological and operational trends. One prominent trend is the adoption of continuous bioprocessing, which improves productivity, consistency, and resource utilization compared to traditional batch processes.

Automation and digitalization play a central role. Manufacturers increasingly deploy artificial intelligence, machine learning, and digital twins to optimize process control, reduce downtime, and improve yield predictability. Real-time monitoring enhances quality assurance and regulatory compliance.

Sustainability influences production strategies. Companies focus on reducing water usage, energy consumption, and waste generation through process intensification and bio-based raw materials. Circular bioeconomy principles gain importance across industrial biomanufacturing.

Regionally, North America leads in technology adoption due to strong biopharmaceutical R&D investment and manufacturing capacity. Europe emphasizes sustainable biomanufacturing and regulatory harmonization. Asia-Pacific shows rapid growth driven by expanding biopharma production, government incentives, and growing domestic demand.

Challenges

The next-generation biomanufacturing market faces technical, regulatory, and economic challenges. Regulatory frameworks for advanced therapies remain complex, requiring extensive validation and quality control. Approval timelines increase development costs and time-to-market.

High initial investment in advanced equipment, automation, and digital infrastructure creates financial barriers for small and mid-sized manufacturers. Skilled workforce shortages in bioprocess engineering and data analytics further constrain adoption.

Supply chain dependencies for raw materials such as culture media, single-use components, and specialized enzymes introduce operational risks. Global disruptions can affect production continuity and cost stability.

Data integrity and cybersecurity risks increase with digitalized manufacturing systems. Protecting proprietary processes and patient-related data remains a priority concern for manufacturers.

Market Scope

Segmentation by Type

Single-Use Biomanufacturing Systems

Continuous Bioprocessing Platforms

Modular and Flexible Manufacturing Facilities

Cell and Gene Therapy Manufacturing Systems

Segmentation by Technology

Synthetic Biology

Process Analytical Technology (PAT)

Automation and Robotics

Artificial Intelligence and Digital Twins

Advanced Cell Culture and Fermentation

Segmentation by Application

Biopharmaceutical Production

Vaccine Manufacturing

Cell and Gene Therapies

Industrial Enzymes and Chemicals

Bio-based Materials and Ingredients

Regional Analysis

North America: Largest market with strong biopharmaceutical production and innovation ecosystem

Europe: Focus on sustainable biomanufacturing and regulatory standardization

Asia-Pacific: Fastest-growing region driven by China, India, South Korea, and Singapore

Latin America: Emerging growth supported by public-private partnerships

Middle East & Africa: Early-stage adoption with investments in biotechnology infrastructure

End-User Industries

Pharmaceutical and Biotechnology Companies

Contract Development and Manufacturing Organizations (CDMOs)

Academic and Research Institutions

Industrial Biotechnology Firms

Government and Public Health Agencies

Market Size and Factors Driving Growth

The global next-generation biomanufacturing market size was valued at USD 26.61 billion in 2024 and is expected to reach USD 56.43 billion by 2032, at a CAGR of 9.85% during the forecast period

Key growth drivers include increasing demand for biologics and advanced therapies, particularly monoclonal antibodies, mRNA vaccines, and personalized treatments. Technological innovation reduces production costs and enhances scalability, making advanced therapies more accessible.

Population growth, aging demographics, and rising prevalence of chronic diseases increase demand for complex biologics. Policy support for domestic biomanufacturing capacity, pandemic preparedness, and bioeconomy development strengthens market expansion.

Sustainability initiatives encourage adoption of energy-efficient processes and renewable feedstocks. Emerging regions present strong opportunities due to expanding healthcare infrastructure, growing biotech investments, and government-backed manufacturing programs.

Conclusion

The next-generation biomanufacturing market demonstrates strong growth potential driven by innovation, healthcare demand, and sustainability priorities. Advanced manufacturing platforms enable faster development, improved quality, and greater flexibility across biopharmaceutical and industrial applications.

Innovation remains critical to address regulatory complexity, workforce challenges, and supply chain resilience. Sustainable manufacturing practices and digital transformation will define long-term competitiveness.

Stakeholders including pharmaceutical companies, CDMOs, technology providers, and policymakers stand to benefit from continued investment and global expansion through 2035.

Frequently Asked Questions (FAQ)

1. What is next-generation biomanufacturing?

It refers to advanced biological production systems that use modern technologies to manufacture biologics, vaccines, and bio-based products efficiently and sustainably.

2. What is the current size of the next-generation biomanufacturing market?

The market is valued at approximately USD 22–24 billion as of 2024.

3. What is the expected growth rate of the market?

The market is projected to grow at a CAGR of around 9–10% through 2035.

4. Which applications dominate the market?

Biopharmaceutical production and cell and gene therapy manufacturing are the leading applications.

5. Which region leads the next-generation biomanufacturing market?

North America holds the largest share due to strong biopharma manufacturing capacity and innovation.

6. What are the main challenges in this market?

Regulatory complexity, high capital costs, workforce shortages, and supply chain risks are key challenges.

7. What future opportunities exist in next-generation biomanufacturing?

Opportunities include continuous processing, sustainable biomanufacturing, digital twins, and expansion in emerging biotech markets.

Browse More Reports:

Global Thermocouple Market

Global Transcranial Magnetic Stimulator Market

Global Urine Test Strips Market

Global Vitamin - Mineral Premixes Market

Global Wearable Tracking Devices Market

Global Vinyl Acetate Emulsions Market

Global High Temperature Grease Market

Global Liquid Waste Management Market

Global Plastic Additives Market

Global Well Casing Market

Global Anti-Slip Coatings Market

Global Apheresis Equipment Market

Global Benign Prostatic Hyperplasia Devices Market

Global Commercial Turf Utility Vehicle Market

Global Doy Pouch Packaging Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- [javascript protected email address]

pallavideshpande

pallavideshpande

emmalu222

emmalu222 ameliano111

ameliano111 davidtha

davidtha rawev69

rawev69